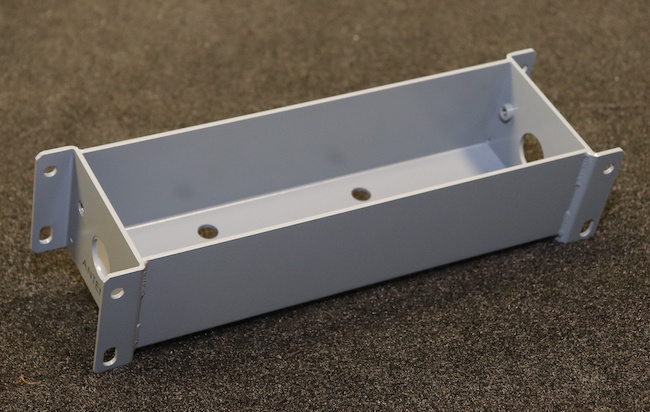

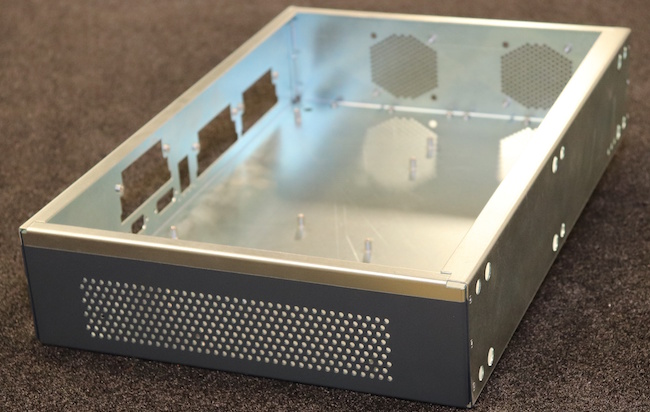

Sheet Metal Fabrication

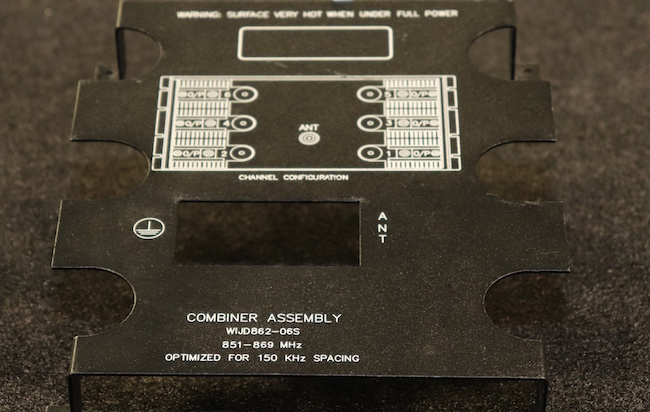

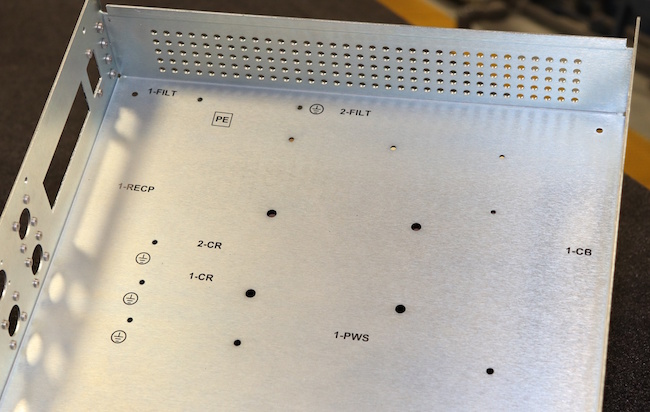

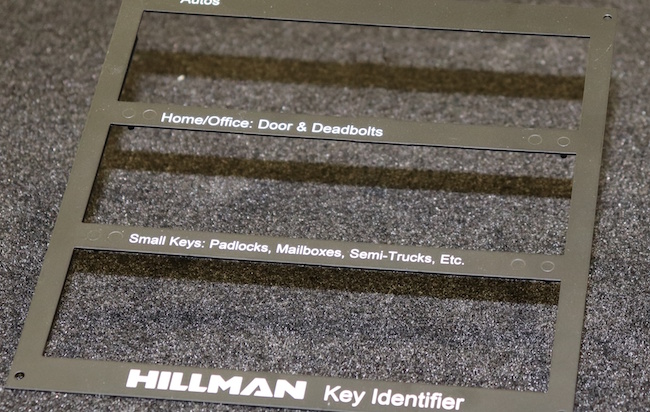

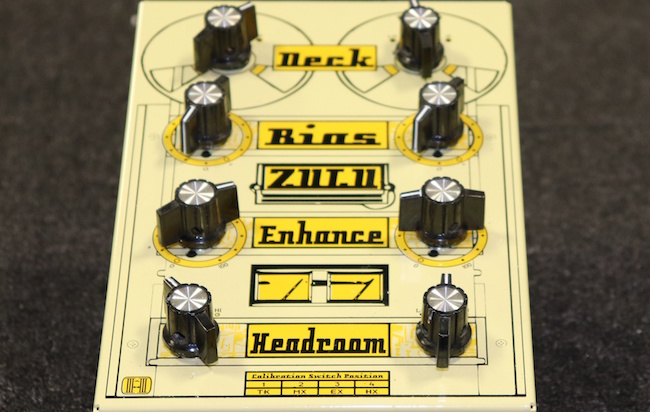

With over 100,000 square feet of manufacturing space in multiple locations our precision sheet metal fabrication facilities can lead our clients from a concept to a finished part completely in house. They have design, optimization and a qualified engineering staff to assist you in implementation of your project for the best possible cost and outcome. With secondary operations fully in house, they can build and completely finish your unit to your specifications including both powder and wet paint applications. Once finished, they also offer kitting, assembly and packaging as needed.

Capabilities

Shearing

Punching

Deburring

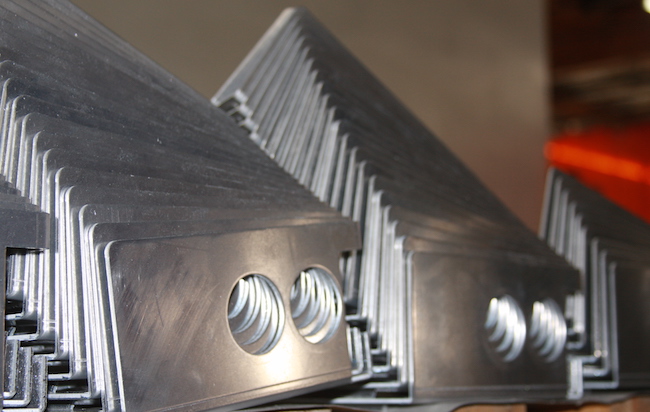

Forming

- Wysong MTH 350-168 14’ Hydraulic Brake, 350 ton

- Amada HFB 1254 14’ Hydraulic Brake 140 ton

- Amada RG100S 8’ Hydraulic Brake 100 ton

- Amada RG80 8’ Hydraulic Brake 80 ton

- Amada RG50 6; Hydraulic Brake 50 ton

- Amada RG35 4’ Hydraulic Brake 30 ton

- Tri-Acro 4’ Hydro-Mechanical Brake 15 ton

- Di-Acro 24” Hand Brake

- Di-Acro Hand Roller

- SL 18 Power Roller

- Ercolina Tube Bending, 3” capacity

- Hines 300 CNC-B Hydraulic Tube Bender 4” capacity

- Ecololina Tube Notching 1”-3” capacity

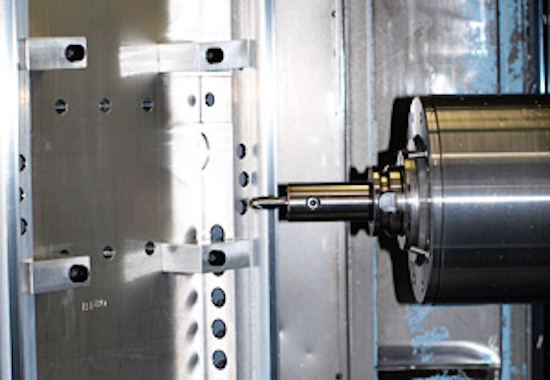

Sawing

- Hyd-Mech Vertical Band Saw

- Doringer Cold Saw

- Hyd-Mech DM-6 Band Saw