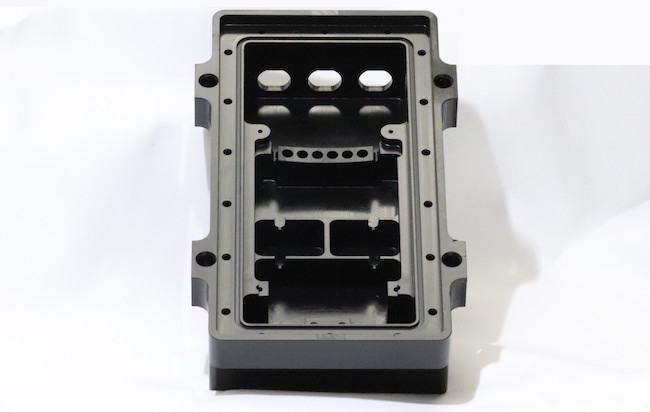

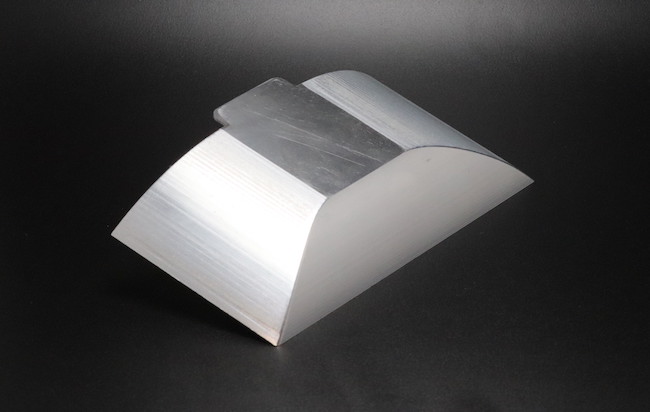

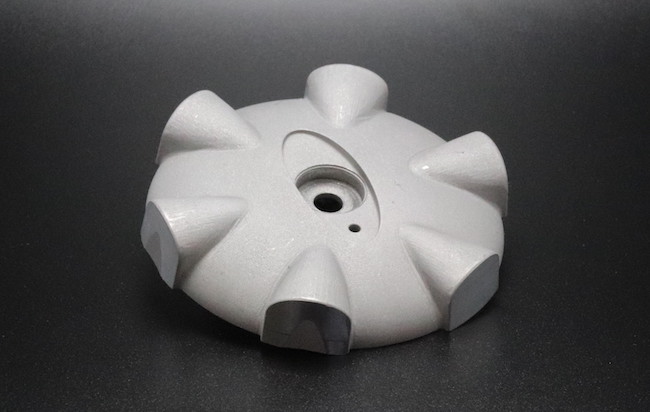

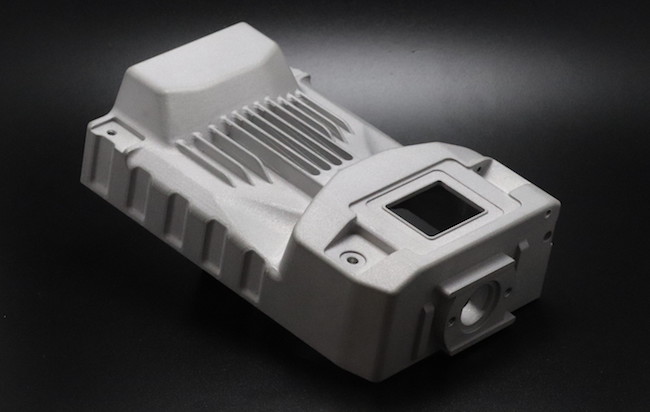

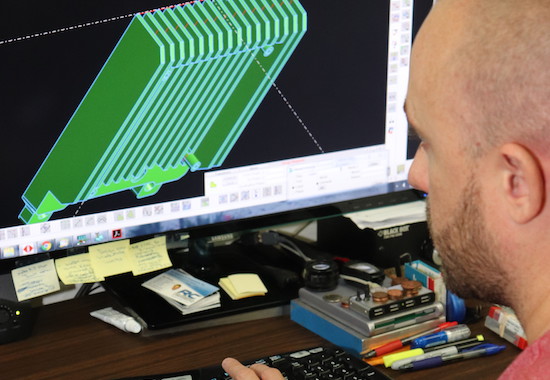

CNC Machining

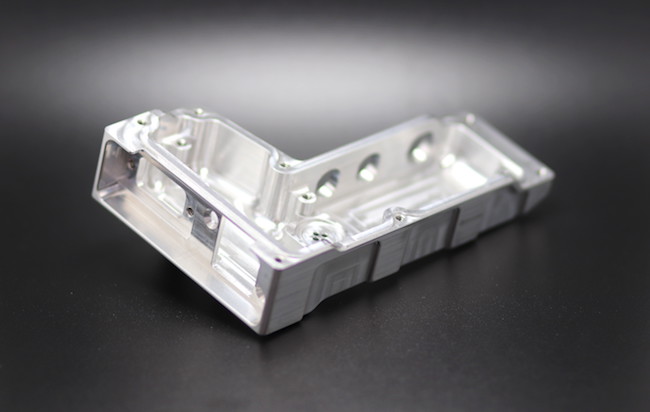

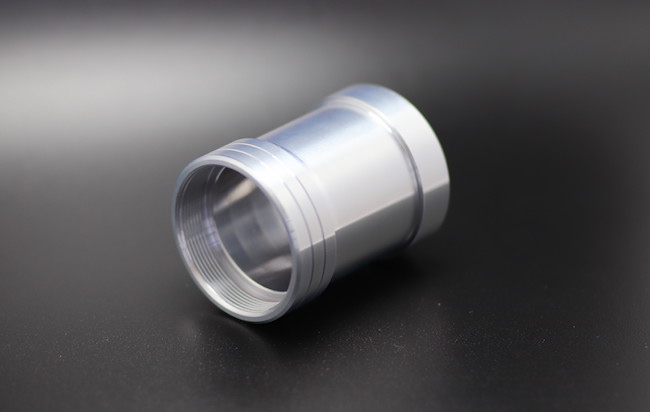

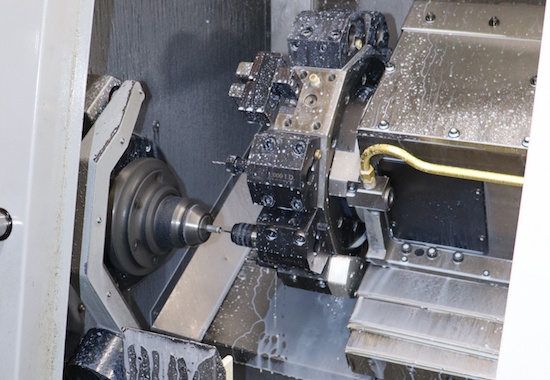

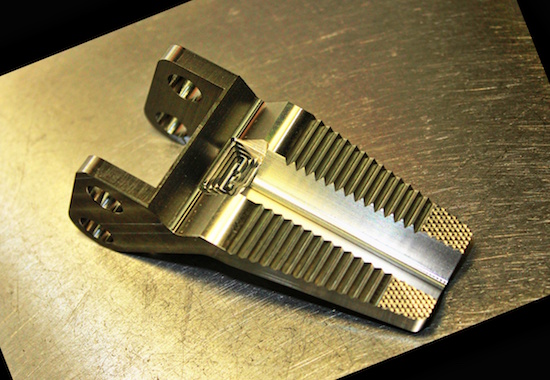

Our CNC Machining manufacturing source strives for constant improvement and education and are not afraid to try new ideas for your project. With this precision machine source, you’ll be working with a partner who consistently produces high quality parts that often cannot be duplicated with other vendors. This CNC Machining principle has decades of experience, running certified multi-shift operations. The core competency in aluminum and plastic will far exceed your expectations in both design fulfillment and quality CNC machined products, delivered on time at an extremely competitive price.