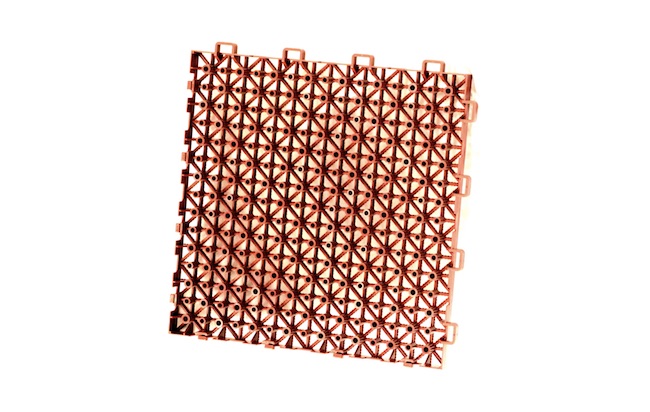

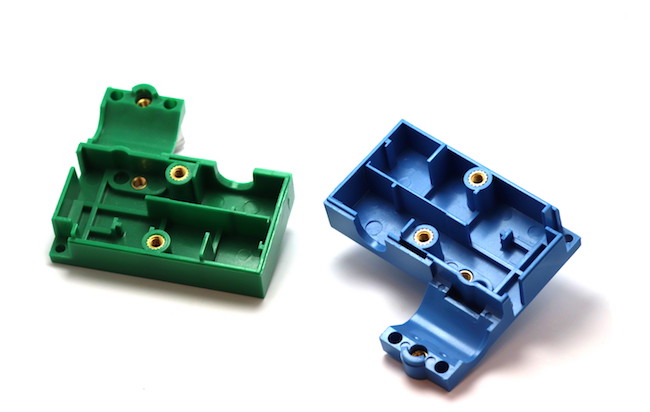

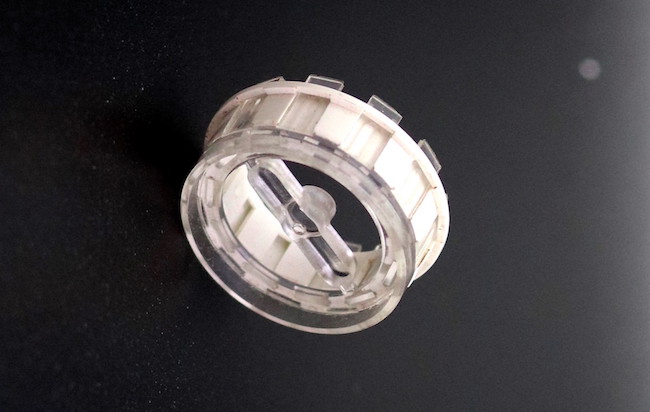

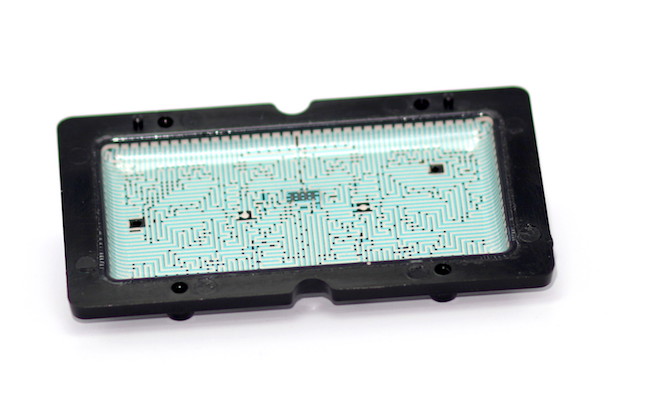

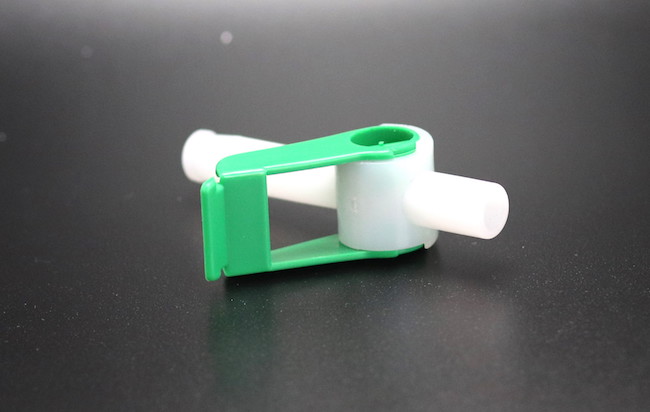

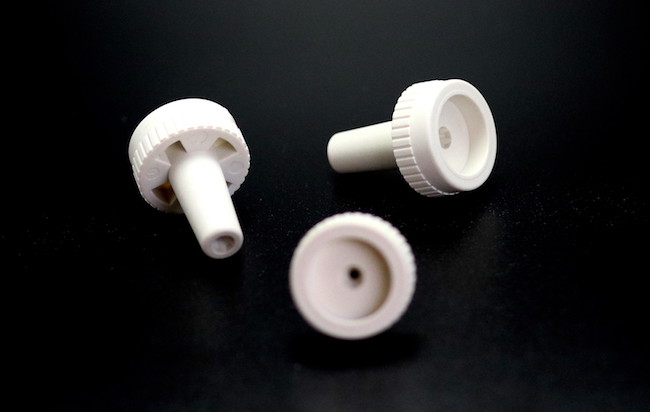

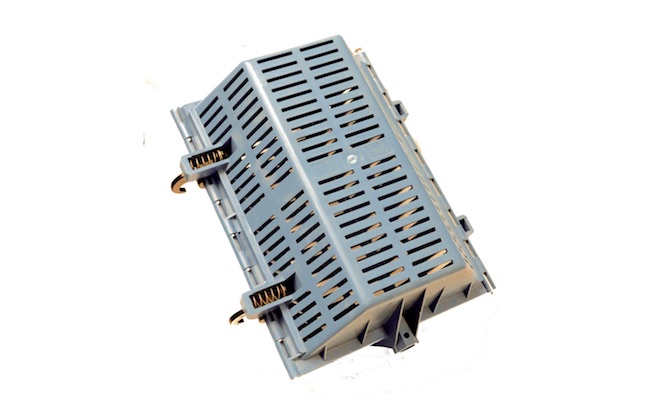

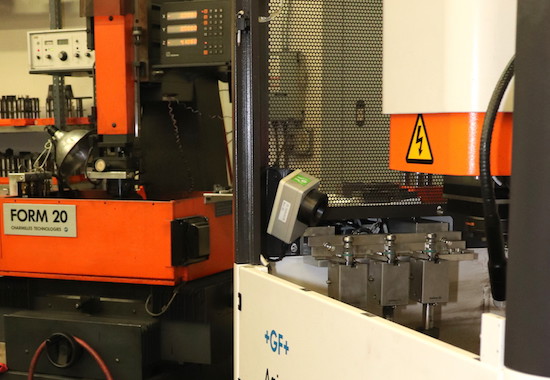

Injection Molding

Gregory and Associates has a variety of injection molding techniques, capabilities, press and shot sizes available. After reviewing your project, our extensive experience in plastics technology will ensure you the best fit possible in terms of desired outcome, cost/benefit and timeline desired. Our resources have years of experience in tooling, molding and secondary operations that cover the full spectrum of available options within the injection molding field.