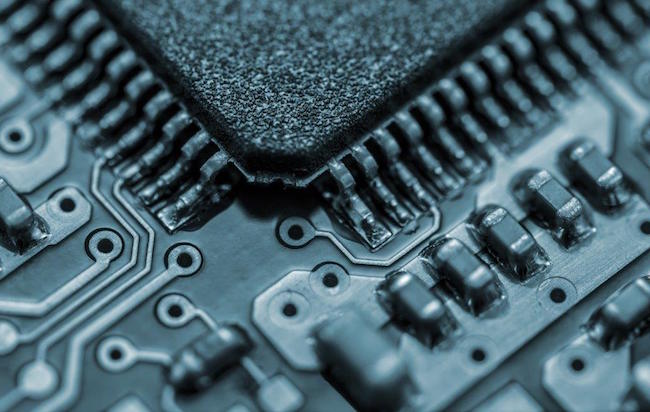

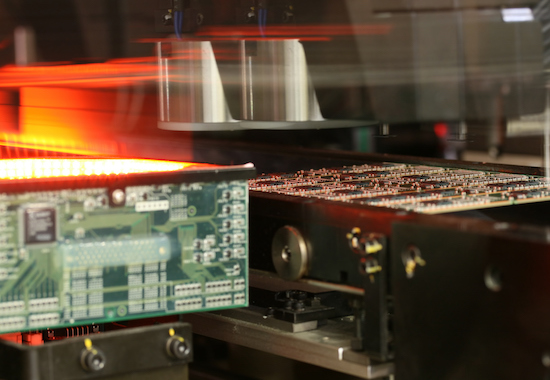

Electronic Board Assembly and Manufacturing Services

Our source for electronic board assembly and box build services is a flexible, responsive and reliable source offering the highest quality product at a competitive price. Their entire operation for Arizona manufacturing sales is built around the highest possible deliverable quality (99.9%) scaled from prototype to full production runs of multiple thousand electronic boards. Their ability to accomplish complete box builds, supplying all needed components or utilizing client supplied parts, allows a full turnkey operation for companies in need of a full service operation.

Capabilities

Electronic Board Materials/Substrates

- Rigid

- Rigid-Flex

- Full Flex

- Standard FR4

- Copper and Aluminum clad

SMT Placement

- High Speed SMT

- Discrete to 0201

- Pitches to .03mm

- BGA,LGA,QFN,POP,CSP

- Space/Trace to .0025

- Through Hole

- Selective Solder

- Press Fit to 20 tons

- Custom Press tooling

Manufacturing Cleanliness

Quality Assurance for Electronic Board Assemblies

- Certifications

- AS9100

- ITAR

- On-site training

- IPC-A-610

- J-STD-001

- Quality programs

- New Production Introduction – NPI

- Design for Manufacturing – DFM

- Stencil Aperture Optimization

- Supplier Quality Management Program – SQMP

- Statistical Process Control – SPC

- 100% Final Quality Inspection

- First Article Inspection (F/A)

- Risk Assessments

- Key Process Indicators

- Continual Improvement

- Equipment

- 3D Solder Joint Inspection with 1 micron accuracy

- X-Ray

- 200X magnification

- Void Measurement

- BGA Analysis

Support - Added Value

- Automated MRP/ERP

- Component Traceability

- RoHS Conversion Services

- Obsolete Assistance

- Inventory Management

- Life-Cycle/Risk Analysis

- BOM Cost Analysis and Reduction

- Bonded Inventory Options

Additional Manufacturing Operations

- Electro-mechanical box build

- One line item purchasing

- Tested to client specifications

- Complete assembly, branding and packaging

- Cable Services

- Custom Cable Assemblies

- Wire Harnesses

- Over molding/Encapsulation

- Continuity testing

- Testing

- Functional

- JTAG/Boundary Scan

- Flying probe

- Burn-in

- Hi-pot

- Conformal Coatings

- Acrylic

- Silicone

- Urethane

- Bonding

- Parylene-C

- Potting

- Encapsulation

- Under fills

Software and Specifications Needed For Quoting and Production

- Gerber File

- BOM